We specialize in accurate steel joist and deck detailing services that ensure precision, safety, and compliance with industry standards. With 17+ years of expertise, our team delivers high-quality drawings that support fabricators, architects, and builders, helping them streamline construction processes while saving time and reducing project costs.

Read More

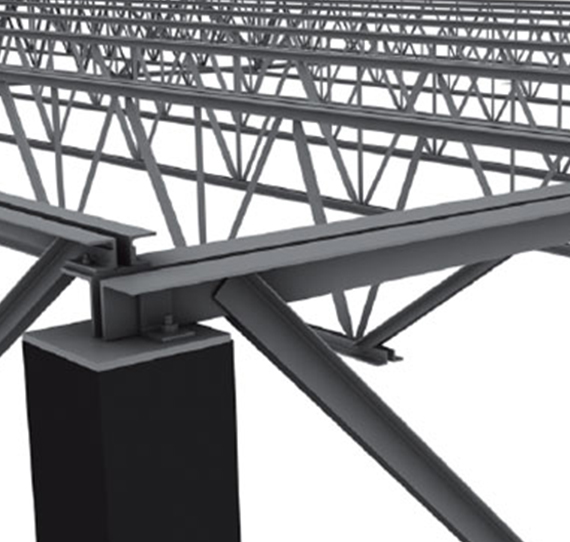

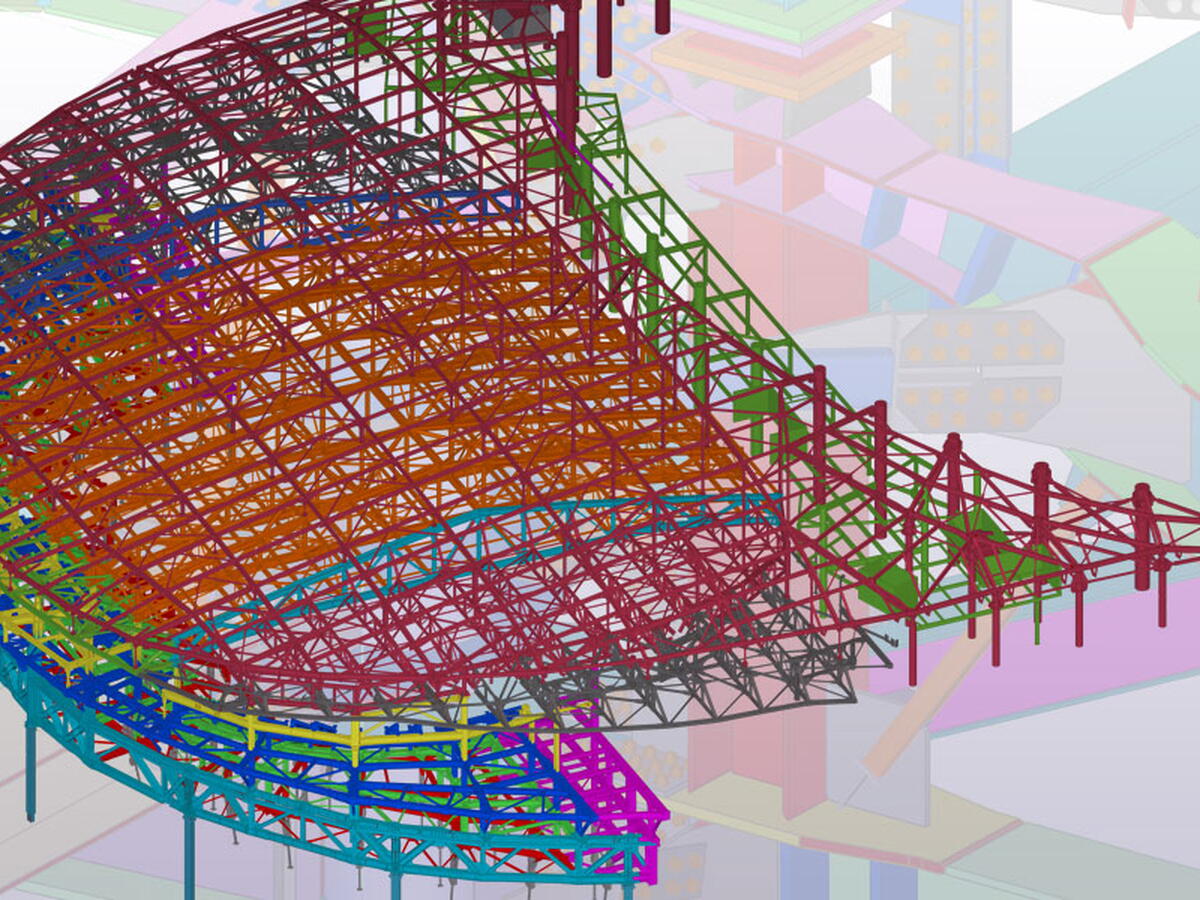

Our structural steel detailing service provides comprehensive shop and erection drawings tailored to client specifications. Using advanced tools like AutoCAD and Bluebeam, we ensure every component is designed with accuracy and efficiency, enabling fabricators and contractors to execute projects smoothly while maintaining international quality and safety standards.

Read More

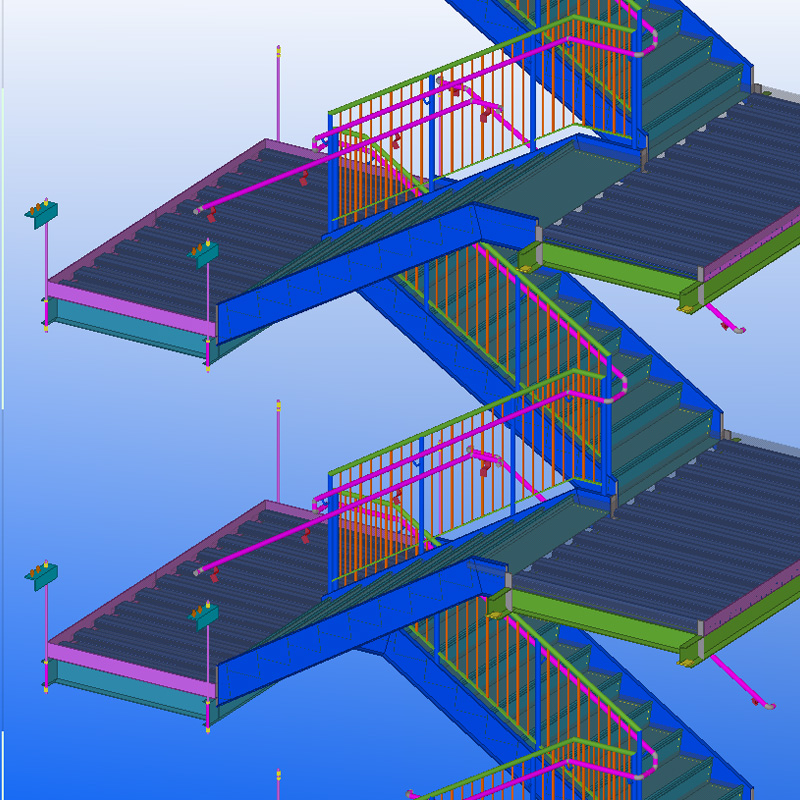

We offer detailed drafting solutions for miscellaneous steel items including ladders, stairs, handrails, and other secondary steel structures. Our team focuses on precision and cost-effectiveness, delivering clear and accurate drawings that help fabricators and construction teams achieve seamless project execution while maintaining strength, durability, and compliance.

Read More

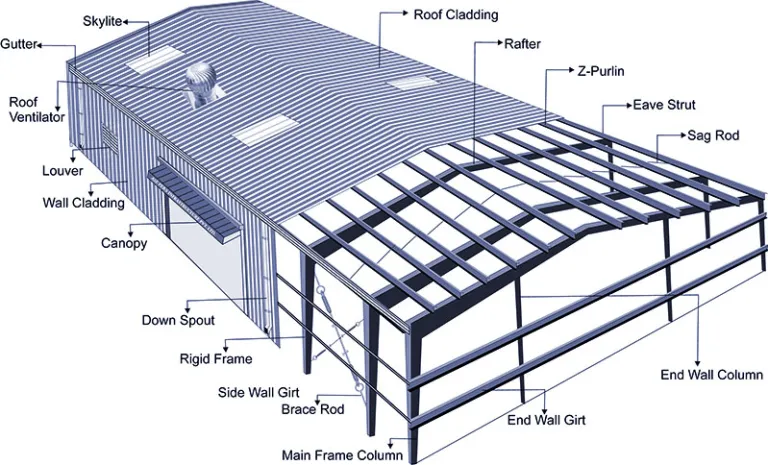

Our pre-engineered building detailing services provide precise layouts and connections that simplify fabrication and erection processes. With extensive experience in PEB detailing, we help clients reduce errors, enhance efficiency, and achieve timely project delivery. Our focus is on accuracy, cost savings, and adherence to global standards for sustainable construction.

Read More